Stop Guessing, Start Profiting: Why a Line Laser is Your Sawmill’s Most Important Tool

Share

If you run a sawmill, you know the drill: wood is money. Every wasted millimeter, every misaligned cut, and every minute of downtime cuts directly into your bottom line.

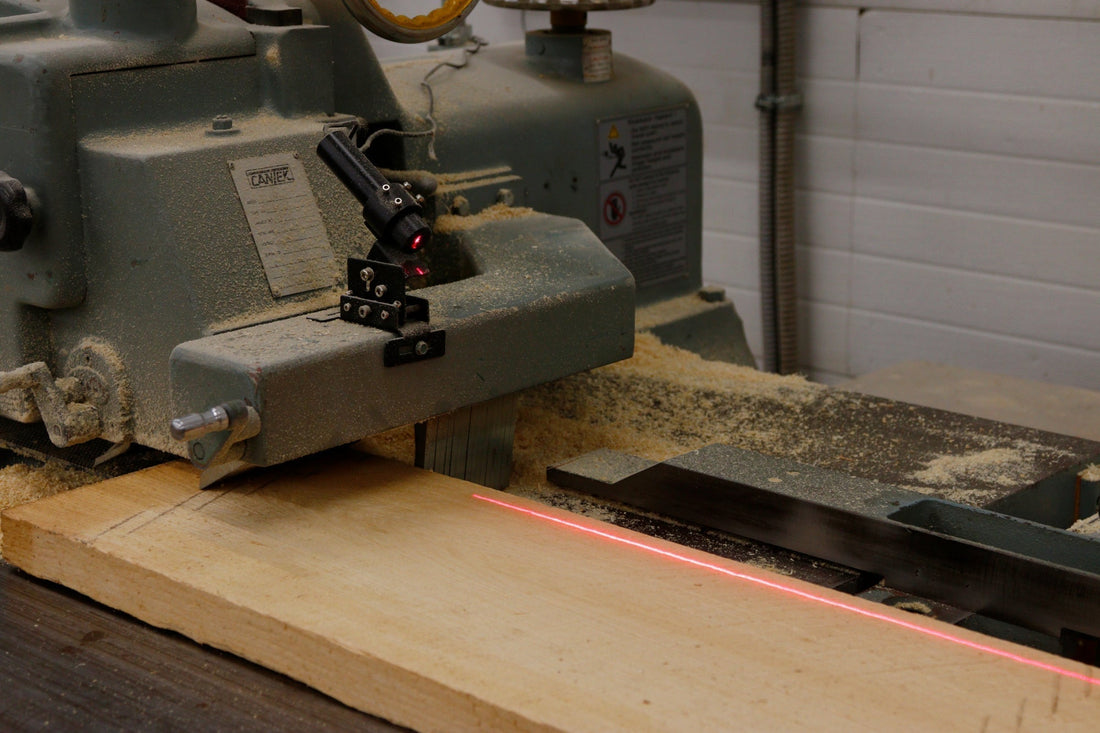

The good news? The days of "eyeballing it" or relying on frayed wires and manual measurements are over. Modern line laser guides are the single fastest and most affordable way to boost your sawmill’s accuracy, efficiency, and profits.

This isn't just about a bright line; it’s about converting more of your raw material into high-value lumber.

1. The Real Cost of a Bad Cut

Think about the waste in your operation right now. A common industry finding is that simply replacing old, inaccurate alignment methods with a precision laser guide can reduce errors enough to increase your yield by 1% to 2%.

What does that mean for you? For a typical mid-sized mill, a 1% yield increase can translate to over $100,000 in extra annual revenue. The laser pays for itself almost instantly.

2. Choosing Your Power: Red vs. Green Laser

The two biggest factors for a laser guide are the output Power (mW) and Color. Both of these depend on your situtation and mill environment.

Power: How Bright is Bright Enough?

Laser power is measured in milliwatts (mW). The brighter the line, the better the visibility under brighter lighting. In most standard indoor operations a 30mw is a very workable brightness but for areas with more ambient light and direct sunlight a 120mw or brighter helps give that extra edge of brightness.

- 30mw: Great for most applications from headsaws, bandmills, edgers, straightline rips etc. that are inside a building and operating under artificial lighting or limited ambient light.

-

120 mW: An extra edge of brightness for brighter environments where sunlight is hitting the saw. These lasers run slightly hotter than the 30mw because of higher power but may give an edge in brightness to help you see your line in daylight.

Color: Why Green Wins in a Sawmill

The human eye is simply more sensitive to the green spectrum.

-

Green Lasers: Appear up to 4 times brighter than a red laser of the same power. They are the clear choice for high-speed edgers, headsaws, or any application where you need perfect visibility on dark or wet timber.

-

Red Lasers: Have a lower power draw and are much dimmer. Great for alternate marking colors or dark environments where green may be too bright.

3. Built for the Battle: Durability and Reliability

A sawmill is a brutal environment. Your equipment faces continuous vibration, fine sawdust, and moisture. Your laser guide needs to be a tool, not a fragile instrument.

Look for these key features to ensure your investment lasts:

-

High IP Rating (IP67 or higher): This is the Ingress Protection rating. An IP67 rating means the housing is completely protected against dust (6) and can withstand temporary immersion in water (7). Our lasers at TrueCut are all rated at IP67 and can take moisture and dust with ease.

-

Rugged Housing: Choose units built with stainless steel or aluminum, designed with advanced heat-sinks to prevent overheating—a common failure point in high-powered lasers.

-

Shock & Vibration Resistance: Components must be industrial grade to handle the continuous jarring and vibration of equipment.

Ready to Maximize Your Recovery?

A line laser guide is more than a convenience; it’s an essential profit center. You’re not just buying a beam of light—you’re buying precision, speed, and the confidence that you are getting the most value out of every single log.

Don't wait to turn wasted material into profit.

📞 CALL US TODAY for a free consultation on the best laser power and color for your specific mill application.

[606-278-2014] | [truecutlasers@gmail.com]